Heat exchanger

Classification:

Product Description

Product Description

The fixed tube sheet heat exchanger consists of two end tube sheets and a shell. Due to its simple structure, it is widely used. The fixed tube sheet heat exchanger is an energy-saving device that facilitates heat transfer between materials and is commonly used in industries such as petroleum, chemical, metallurgy, power, light industry, and food. In refining and chemical plants, heat exchangers account for about 40% of the total equipment and 30%-45% of the total investment. In recent years, with the development of energy-saving technologies, the application fields have continuously expanded, and the use of heat exchangers for high-temperature and low-temperature energy recovery has brought significant economic benefits.

Composition of Fixed Tube Sheet Heat Exchanger

The fixed tube sheet heat exchanger is composed of components such as a tube box, shell, tube sheets, and tubes. Its structure is relatively compact, allowing for more tubes under the same diameter, resulting in a larger area and simpler manufacturing.

The structural feature of the fixed tube sheet heat exchanger is that a tube bundle is set within the shell, with the ends of the tube bundle fixed to the tube sheets by welding or expansion methods. The two end tube sheets are directly welded to the shell, and the inlet and outlet pipes of the shell side are directly welded to the shell. The tube sheets and tube box flanges are fastened with bolts, and the inlet and outlet pipes of the tube side are directly welded to the tube box. Several baffle plates are set inside the tube bundle according to the length of the heat exchange tubes. This type of heat exchanger can be divided into multiple passes using partitions.

Characteristics of Fixed Tube Sheet Heat Exchanger

The fixed tube sheet heat exchanger has a simple structure, low manufacturing cost, easy cleaning of the tube side, and the ability to be divided into multiple passes on the tube side, while the shell side can also be divided into double passes. It has a wide range of specifications, making it widely used in engineering. However, cleaning the shell side is difficult, and it is not suitable for dirty or corrosive media. When the expansion difference is large, an expansion joint can be set on the shell to reduce thermal stress caused by the temperature difference between the tube and shell sides.

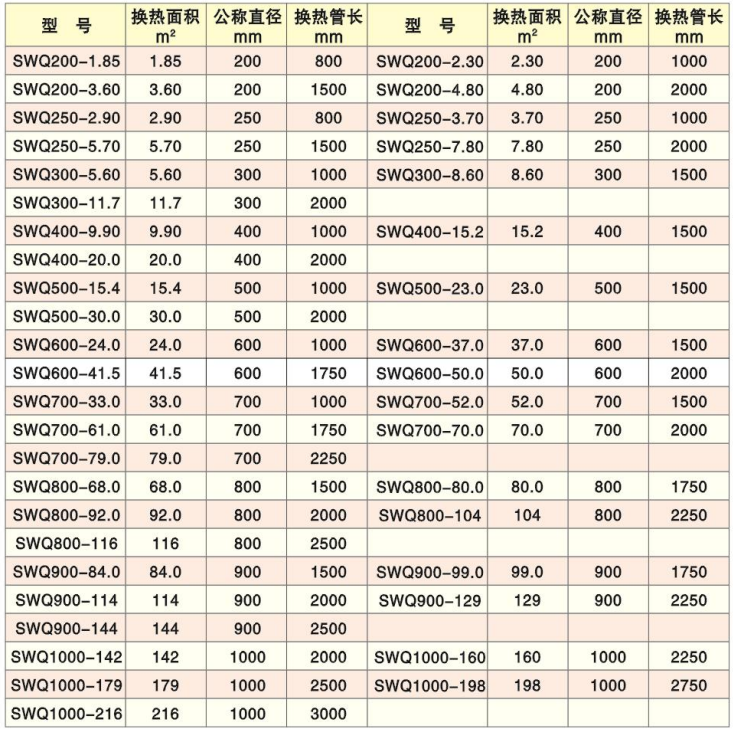

Parameters of Fixed Tube Sheet Heat Exchanger

Key words:

Welcome your message consultation